Although the first recorded casino was legalized in Venice in 1626 and gambling can be traced as far back as ancient civilizations of Mesopotamia and early China the Casino Chip or Cheque is a relative newcomer on the scene.

Prior to the late 19th-century player used almost any variety of small valuable objects imaginable as wagers in their games. Early gamblers often gambled using small pieces of gold or silver, gold nuggets or coins or paper money. These early games had no standardization so saloons and gambling houses in an attempt to bring standardization to their games began to create their own standardized substitute; this is the birth of what would eventually become the casino chip that we know today. Soon it was not uncommon for upscale gambling houses and saloon to have specially made tokens made of ivory or bone while others made do with gambling tokens made of paper and shellac. One of the downsides to these proto-chips is that they were easy to forge so gambling house started put markings, or brands, on these early chips while they searched for a more secure substitute.

This all changed in the 1880’s when companies started to produce chips of uniform size made of clay using a compression mold technique. These chips, made of 100% clay, are the direct ancestors of the casino chips that are used today. The downside to using these 100% clay chips was that they were very fragile and broke easily when handled roughly by the players. This was an issue that casinos would struggle with up unit the early 1950's when the companies that produced them started to add other materials to the clay to increase the durability of the chips. That was when the companies started to add earthen materials such as sand, chalk and clay material similar to the material found in cat litter that the modern clay composite chip that we know today was truly born. The process to make these modern clay composite chips is a trade secret and each manufacturer uses their own recipe of ingredients when making their chips.

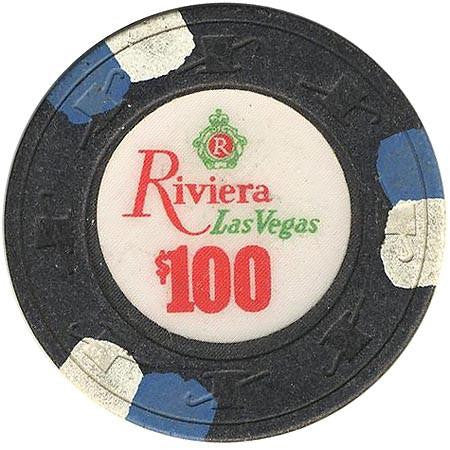

The edge spots on the chips are also made of the same material as the rest of the chip, they are not painted on. To achieve the effect of the edge spot that area of clay is removed and then it is replaced with clay of a different color before the clay blocks are cut into the shape of chips. Any printed graphic or inlay will be put on at this time and covered with a thin layer of plastic; each chip will then receive a mid-inlay, if desired, and the chip is then placed in a special compression mold that bakes and compresses the chip into the proper size, weight and permanently adhering the inlay to the chip.

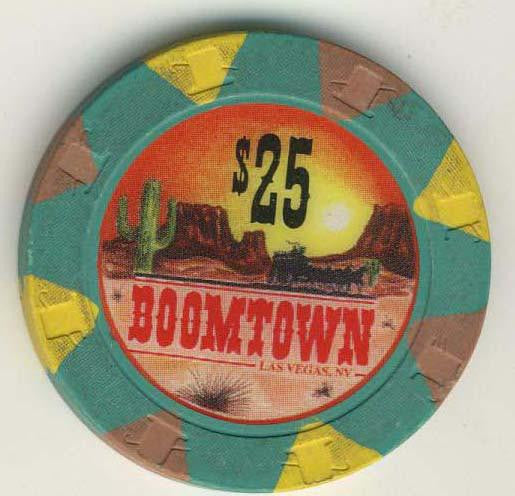

In the mid-1980’s the Ceramic casino chip was introduced as an alternative to the traditional clay composite casino chip. These Ceramic chips have become popular because they allow lettering and graphics on the entire surface of the chip instead of just on the inlay.

In less than 150 years casino chips have come from the crude easy to forge chip made of makeshift materials to the modern chips we know today that boast enhanced security features such as radio frequency identification (RFID), UV markings only visible under a black light and other security features. Only the future knows what is in store for the casino chip of tomorrow.

Mapes Hotel Casino Chip

2 comments

Stephen Christie

I would say thanks firstly to share this wonderful blog which contains amazing and useful information regarding attractive poker chips. I love to play casino games and I usually purchase the casino products online from AmericanGamingSupply.

I would say thanks firstly to share this wonderful blog which contains amazing and useful information regarding attractive poker chips. I love to play casino games and I usually purchase the casino products online from AmericanGamingSupply.

bessyt042

Very informatiove info about your products.

Very informatiove info about your products.